Why Pixel-by-Pixel Calibration is Essential for LED Displays? | Uniformity Fix

Table of Contents

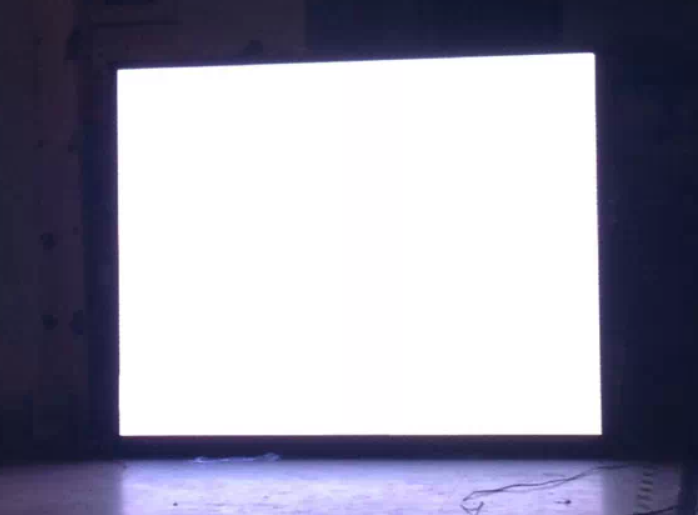

Why LED Displays Require Pixel-by-Pixel Calibration

No two LEDs are identical! Inherent variations in brightness, chromaticity, and performance arise from:

- LED Production Variations: Chip size, bonding angle, phosphor purity, and binning tolerances (±1nm wavelength, ±10% brightness).

- Assembly Imperfections: Lamp insertion angles, mask alignment, module/panel flatness.

- Environmental Factors: Uneven thermal stress, differential aging (e.g., red LEDs decay faster than blue).

These combined factors cause visible “color mura” (patchy discoloration), degrading image fidelity.

What is Pixel-by-Pixel Calibration?

A precision technique that:

- Measures brightness/chromaticity of every sub-pixel (R/G/B) using spectroradiometers (e.g., Konica Minolta CL-500A).

- Generates calibration coefficient matrices for each sub-pixel.

- Adjusts driving current per pixel via the display control system.

Result: Uniform color reproduction (>95% brightness consistency) and true-to-source imagery.

⚠️ Limitation: Calibration balances brightness by reducing overly bright pixels—it cannot boost dim LEDs or fix hardware flaws (e.g., faulty resistors, damaged wiring).

Pre-Calibration Checklist

Tools & Environment

Category Requirements

Measurement Gear Spectroradiometer, colorimeter, luminance meter

Hardware Laptop with calibration software, data cables, screwdrivers

Environment Wind/rain-free; stable D65 ambient light; screen surface dust-free

Display Pre-Treatment

Clean: Remove dust/grime from lamps and masks (dirt causes up to 15% measurement error).- Replace Defective Modules: Fix dead LEDs (>3% failure rate), abnormal scanning, or dim zones.

- Upgrade Hardware: Install receiver cards supporting pixel-level calibration.

Step-by-Step Calibration Guide

Phase 1: Baseline Settings

- Brightness: 1.5–2× ambient light (e.g., 500–600 cd/m² for 300 lux environments).

- Contrast: 80–90%.

- Color Temp: 6500K (broadcast), 5500–6000K (conference rooms).

- Gamma: Start at 2.2; increase to 2.4 if shadows lack detail.

Phase 2: Pixel Calibration

- Scan: Use software to map brightness of every module (flag areas >5% deviation).

- Adjust: Tweak RGB values (<3% per iteration) until uniformity achieved.

Phase 3: Color Refinement

- Gamma Tuning: Import sRGB curve; fine-tune to prevent blown highlights/crushed shadows.

- White Balance: Measure actual vs. target color temp (e.g., reduce blue gain if exceeding 7000K).

Pixel Calibration FAQs

1. Can any LED display be calibrated?

→ Yes, if the control system supports it. New/old screens benefit from calibration.

2. Does binning (±1nm) replace calibration?

→ No! Binning only addresses initial LED variance. Post-assembly errors, aging (72+ hrs), and differential decay require calibration. Recalibrate every 1–2 years.

3. Calibration time for 100m² screen?

→ 4–6 hours (outdoor installations).

4. Can calibration fix mixed lamp types?

→ Partially. It corrects brightness/color but can’t alter beam angles (e.g., mixing round vs. oval LEDs).

5. Handling hardware replacements?

→ Cloud-backed calibration profiles allow seamless reconfiguration.

Pro Tip: Demand factory calibration reports when purchasing displays. For complex issues, consult manufacturer support.

Contact us today to explore how our professional LED displays can transform your visual environment!