What is COB LED Technology? A Complete Guide & Industry Applications

Table of Contents

Introduction to COB LED Technology

COB (Chip on Board) LED technology is an advanced lighting solution that integrates multiple LED chips directly onto a single substrate, forming a compact and high-intensity light source. Compared to traditional LED packaging methods like DIP (Dual In-Line Package) and SMD (Surface-Mounted Device), COB LEDs offer enhanced efficiency, better heat dissipation, and improved performance.

In this guide, we will explore the fundamentals of COB LED technology, its advantages, applications, comparisons with other LED types, and why it is gaining traction in industries such as display technology, lighting solutions, and automotive applications.

How Does COB LED Technology Work?

COB LED technology involves placing multiple LED chips directly onto a circuit board with a single shared phosphor layer. Unlike SMD LEDs, where each diode is individually encapsulated, COB LEDs appear as a single light source due to their compact arrangement.

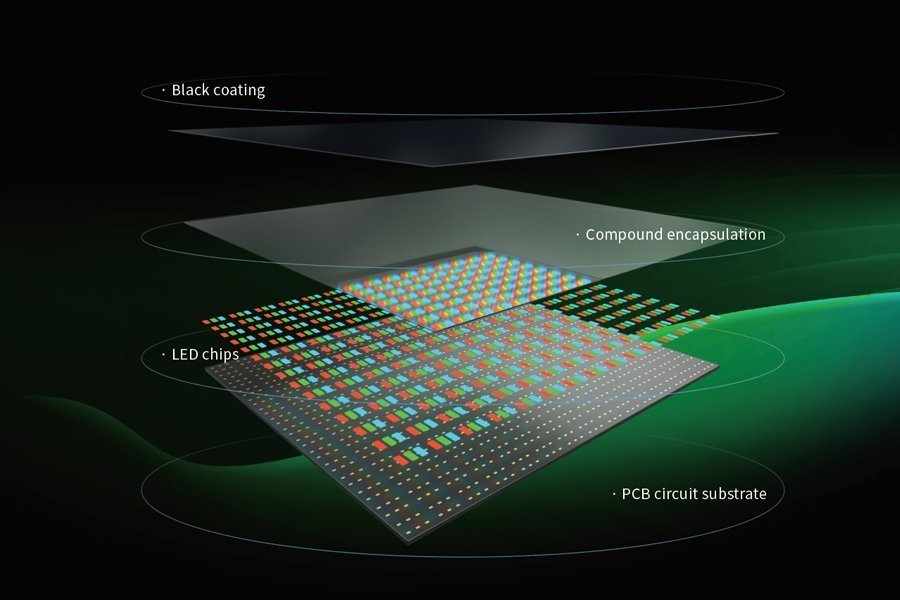

Key Components of COB LEDs:

LED Chips – Multiple LED chips (usually more than 9) are mounted closely together.

Substrate – The base material, often aluminum or ceramic, which aids in heat dissipation.

Phosphor Coating – A uniform layer that converts blue light to white light, improving color consistency.

Encapsulation – A protective layer that enhances durability and reduces glare.

Advantages of COB LED Technology

COB LED technology offers numerous benefits over traditional LED solutions, making it a preferred choice for various applications.

Higher Luminous Efficiency

COB LEDs have a higher lumen-per-watt ratio, making them more energy-efficient. Since multiple LED chips share a single circuit, they reduce power consumption while delivering brighter illumination.

Improved Heat Dissipation

The compact design of COB LEDs allows better heat management. The larger surface area of the substrate enables efficient thermal conduction, reducing the risk of overheating and prolonging lifespan.

Uniform Light Output

Unlike SMD LEDs, which consist of multiple point sources, COB LEDs emit a more even and glare-free light, improving visual comfort in applications such as indoor lighting and LED displays.

Compact Design and Space Saving

COB LEDs integrate multiple diodes in a single package, allowing for a smaller footprint compared to traditional LEDs. This makes them ideal for applications requiring high brightness in limited space.

Enhanced Durability and Reliability

With fewer soldering points than SMD LEDs, COB LEDs reduce the likelihood of connection failures. Their robust build quality ensures long-term performance in demanding environments.

Applications of COB LED Technology

COB LEDs are widely used in various industries due to their superior performance. Here are some common applications:

LED Displays and Video Walls

COB technology is gaining popularity in LED display solutions, especially for high-resolution indoor LED screens. It offers:

High contrast ratios for vibrant visuals.

Seamless design with fewer visible gaps.

Improved durability against dust and moisture.

General Lighting Solutions

COB LEDs are extensively used in residential, commercial, and industrial lighting, including:

Downlights and spotlights for focused illumination.

Street lighting for energy-efficient outdoor lighting.

Track lighting for enhanced retail displays.

Automotive and Aviation Lighting

COB LEDs are preferred for vehicle headlights and aircraft lighting due to their:

High brightness output

Better visibility and safety

Energy efficiency

Medical and Industrial Equipment

COB LEDs are used in medical imaging devices, microscopes, and industrial inspection tools, benefiting from:

Precise color rendering

Consistent light output

Low power consumption

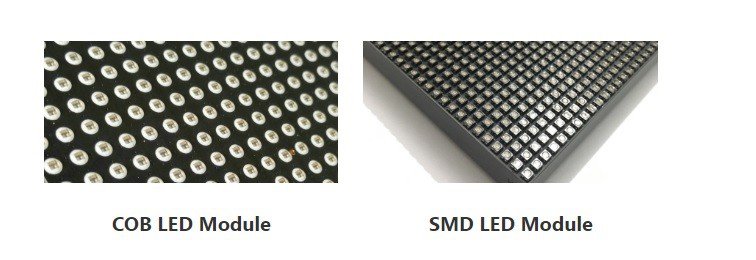

COB LED vs. SMD LED: Which is Better?

| Feature | COB LED | SMD LED |

|---|---|---|

| Design | Multiple chips on one substrate | Individual chips separately packaged |

| Brightness | Higher luminous efficiency | Moderate brightness |

| Heat Dissipation | Better thermal management | Requires additional cooling |

| Light Uniformity | Soft, glare-free light | Visible multiple points of light |

| Durability | Higher reliability due to fewer solder points | More prone to failure at solder joints |

Which one should you choose?

If you need uniform lighting with high efficiency, go for COB LEDs.

If you require flexible configurations and lower costs, SMD LEDs might be a better option.

The Future of COB LED Technology

As LED technology advances, COB LEDs continue to evolve with new developments such as:

Mini COB and Micro COB for ultra-fine pixel pitches in LED displays.

Improved thermal management solutions for increased lifespan.

Enhanced phosphor coatings for better color accuracy.

Integration with smart lighting and IoT applications.

Conclusion: Why Choose COB LEDs?

COB LED technology offers superior brightness, efficiency, and durability, making it an excellent choice for applications ranging from LED displays to general lighting. Whether you’re looking for high-resolution display solutions or energy-efficient lighting, COB LEDs provide a future-proof solution with long-term benefits.

For businesses investing in LED technology, understanding COB vs. other LED types can help optimize costs and performance. If you’re considering upgrading your lighting or display systems, COB LED technology is definitely worth exploring.

Contact us today to explore how our professional LED displays can transform your bars’visual environment!